By now, the strings are set in place and I'm happy with their

location. It's time to start adjusting the slots to their final height.

I'm going to use this page to discuss various ways to set nut slot height.

|

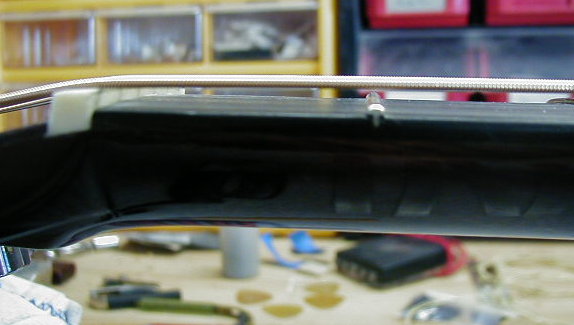

From the side you can see how shallow the nut slots are

at this stage and how high off the frets the strings are. |

|

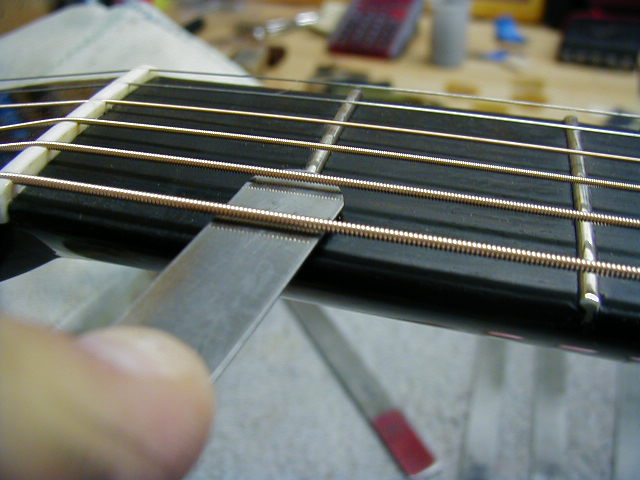

This is the basic method of setting nut slot

height. Hold the string between the 2nd and 3rd fret and adjust

the nut slot that each string just barely clears the 1st fret. The

distance is so small that I can't even photograph it. It'll be

just a sliver of light.

The above

technique takes the action out of consideration and sets the nut slot at

just above fret height. I'm a firm believer in setting the nut

slots at or just a tiny bit above fret height. That's the height

you're at anytime you put a capo on the guitar.

|

|

After using the above technique, I still like to

measure the open string. It's a larger gap and is easy to measure.

I've adjusted the slot to change the open measurement .002" or so and

seen almost no change in the "gap" but the overall result is better. I

put a capo on the 1st fret (2nd fret shown here- use the 1st) and

measure the clearance at the 2nd fret. Then add .002"-.004" to the

open string, 1st fret measurement. I'll do this for each string.

After you do 100 or so, you'll quickly see that an action of about

.105" will results in a low E nut

slot height of .018" and an action of .095" will produce a nut height of

.016", and so on. I still like to measure each one, though.

|

|

In this shot, I have the low E set and am dropping the

A string down. It's very clear from this shot that you can

accurately measure these things. That's a .022" gauge under the

strings and if you look very closely you can see a tiny sliver of light

under the low E string. There's an obvious gap under the A. I'm

going to set this A to .020", but used this gauge to illustrate a "done"

string and one "yet to be done".

If the string buzzes open, it probably also buzzes at each fret and a

taller saddle is required to raise all the actions. If just the

open string buzzes, then you cut the slot too low or you have sloppy

slots. |

|

Here's the nut roughed out with the string heights set.

I'm ready to remove it, file down the top, polish it and reinstall.

Note that my pencil marks are still there! |

|

And here's the finished nut. It wouldn't hurt for

me to remove just a little more of the top of the nut so that 1/2 the

string is exposed, but it's easy to go just a little too far and ruin

the nut, so I'm probably going to just leave it alone. I've

polished the frets and have glued the nut to the fingerboard with a

smear of bottled hide glue. Note that the tall Grover Rotomatic

tuners give a fairly shallow, and poor, break over the nut. If

those holes were down about the top of the hex nut, we'd get a stronger break angle. |

|

Here's another finished nut, from the top. This

one's made from my "vintage" bone, which has a creamier look to it than

the whiter stuff I was using above. |

And that's a nut The Kimsey Way, folks!!! Yes, I know that Stew Mac

makes a cool little gauge for spacing nuts, but I have a caliper, math doesn't

scare me, and I'd use the caliper to set the E's from the edge anyway.

Just for reference, it takes me 40 minutes, start (guitar on the bench) to

finish (playing the guitar). The longest time is spent taking the slots

down to the height and then finishing and polishing the nut.